Positive temperature coefficient(PTC) heaters have become the go-to solution for many heating applications — smaller applications, in particular.

PTC is a semiconductor ceramic material that, as its name implies, features a very high positive temperature coefficient; applying power to PTC causes an initial decrease in resistance and a consequent increase in temperature. This reduced resistance allows for an inrush of current upon startup, so PTC heaters reach operational temperatures quickly. The generated heat is both regulated and dissipated by airflow applied to the PTC elements.

PTC加热器在tradit携带许多好处ional heating elements; PTC heaters feature a smaller and slimmer footprint, compatibility with both single and double insulation, automatic cut-off safety fuse protection to avoid abnormally high current and heat, fast thermal response times, and safe underwater use without electricity leakage (when double insulated and depending on the model).

Their compact size and high performance make them ideal for a wide variety of applications, performing well in automotive industry uses — particularly in electric vehicles — as well as dehumidifying and thermal retention applications. They are also used in a range of general-use electronic appliances, commercial and personal alike: hand dryers, air conditioners, irons, both small- and large-scale lamination machines, adhesive sealing machines, and more.

一个t Pelonis Technologies, Inc. (PTI), we offer standard andcustom PTC heatersof two different types, fin heaters and ourproprietary honeycomb heaters.

Fin Heaters

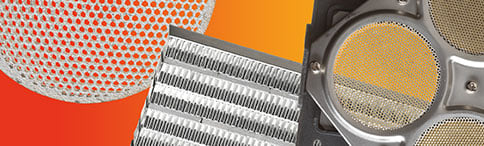

.jpg?width=287&name=4finptc%20(2).jpg) 一个type of electrical resistance heater, fin heaters house their heating elements in rectangular aluminum tubes — between one and three in standard models. The heating element tubes are surrounded by PTC fins, which pick up and transmit heat from the heating elements. The fins provide considerable surface area for heat transference to circulating air, and gaps between the fins allow for a high degree of smooth air movement. The pitch of the fins alters both heating efficiency and air resistance.

一个type of electrical resistance heater, fin heaters house their heating elements in rectangular aluminum tubes — between one and three in standard models. The heating element tubes are surrounded by PTC fins, which pick up and transmit heat from the heating elements. The fins provide considerable surface area for heat transference to circulating air, and gaps between the fins allow for a high degree of smooth air movement. The pitch of the fins alters both heating efficiency and air resistance.

Fin heatersoffer a number of benefits over more conventional heaters, such as those that use coil heating elements. Fin heaters’ reduced size allows for use in a range of small spaces and applications; these heaters also operate much more efficiently, without the decreased heat transfer efficacy experienced by comparably sized conventional heaters. The PTC fins allow our fin heaters to self-regulate, offering fast thermal response, low inrush current, and a diverse selection of efficiency and air resistance options.

Honeycomb Heaters

Honeycomb heatersare small PTC discs that are pierced by more than 1,200 holes, either round or triangular. These heating discs function as the heating element of a heater assembly, as they’re directly connected to the power source; the holes in each disc allow the airflow across the disc to be heated at rates of 100%.

By nature of the Curie temperature point, PTC is self-regulating; the Curie temperature point is the temperature at which the magnetic properties of a material abruptly change, either becoming more or less resistive. In this way, PTC generates more or less heat depending on the ambient temperature of its surroundings.

The air temperature at the point of exit from each individual honeycomb PTC disc is 160°C under typical operation and power of 375 W. If the airflow is decreased, the airflow temperature will increase and the PTC power will decrease. If the airflow keeps decreasing down to zero, the temperature of the PTC will reach its maximum temperature. This is the Curie temperature (Tc), which is about 200°C. Depending on the application requirements, we can adjust the Curie temperature point of honeycomb heating discs and calibrate them to the ambient temperature of virtually any use application.

Fin and Honeycomb: Industrial Heaters Comparison

While both our fin heaters and honeycomb heaters carry a range of benefits over conventional heaters like coil and ceramic chip heaters, they are not equal in performance. The chart below compares fin and honeycomb heaters based on several variables; the more circles, the better the performance.

Honeycomb PTC Heater Assemblies

PTI has also developed a range of honeycomb heater assemblies, currently available in three- disc, four-disc, and five-disc configurations.

These honeycomb heater assemblies offer unmatched performance: The standard three- disc models generate heat output of 1100 Watts (W); the four-disc models generate 1500 W; and the five-disc models generate 2000 W. These heat output levels are as much as 50% higher than similarly sized conventional coil and ceramic chip heaters.

一个lso, the heat transfer rates of honeycomb heaters are superior to any other heater for use in small spaces and can be configured with a variety of fans and blowers to create powerful, compact air heating systems.

Honeycomb heater assemblies are manufactured from high-quality, high-temperature polyphenylene sulfide (PPS) plastic with stainless steel contacts and silver coatings, allowing for industry-leading conductivity and efficiency rates. And perhaps most importantly, honeycomb heaters offer great design flexibility; they can be designed in a wide variety of custom configurations, making them compatible with many diverse applications.

Learn More

Theheating expertsat Pelonis Technologies, Inc. have over 25 years of experience designing and manufacturing unique OEM solutions, the latest of which are our proprietary honeycomb heaters. Interested in learning more or discussing how we can help with your specific needs?Tell us about your project here, and a team member will be in touch to assist you.

Contact

Contact (US) 888-546-0524

(US) 888-546-0524